Comprehensive Guide to Controllers in the Process Industry

In process engineering, controllers play a crucial role in maintaining the desired output of a system by adjusting the inputs based on feedback. Different types of controllers are used depending on the nature of the process, desired control performance, and specific requirements of the system. This article provides an overview of the main types of controllers used in process engineering, including Proportional (P), Integral (I), Derivative (D), Proportional-Integral (PI), Proportional-Derivative (PD), Proportional-Integral-Derivative (PID), and advanced control strategies.

Click Here to Join the Over 5500 Students Taking our Highly Rated Courses in Manufacturing, Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

1. Proportional (P) Controller

Description

A Proportional controller adjusts the control signal in proportion to the error, which is the difference between the setpoint and the process variable. The control law is given by:

u(t)=Kpe(t)

where u(t) is the control signal, Kp is the proportional gain, and e(t) is the error.

When to Use

- Simple systems where the dynamics are straightforward.

- Processes where a steady-state offset can be tolerated.

- Systems that require a quick response.

Advantages

- Easy to implement and tune.

- Provides a fast response to changes in setpoint or disturbances.

Disadvantages

- Steady-state error (offset) is present.

- High gain can lead to instability.

2. Integral (I) Controller

Description

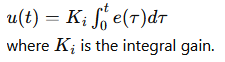

An Integral controller eliminates the steady-state error by integrating the error over time. The control law is:

When to Use

- Systems where eliminating steady-state error is crucial.

- Processes that are relatively slow and where quick response is not critical.

Advantages

- Eliminates steady-state error.

Disadvantages

- Can lead to slow response.

- May cause instability and oscillations if not properly tuned.

Click Here to Join the Over 5500 Students Taking our Highly Rated Courses in Manufacturing, Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

3. Derivative (D) Controller

Description

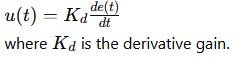

A Derivative controller predicts the future trend of the error by considering its rate of change. The control law is:

When to Use

- Processes with rapid changes or oscillations.

- Systems where anticipating the future trend of the error improves control.

Advantages

- Improves stability and damping.

- Reduces overshoot and oscillations.

Disadvantages

- Sensitive to noise in the error signal.

- Does not eliminate steady-state error.

4. Proportional-Integral (PI) Controller

Description

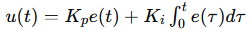

A PI controller combines the proportional and integral actions to provide both quick response and elimination of steady-state error. The control law is:

When to Use

- Systems that require quick response and elimination of steady-state error.

- Processes with moderate dynamics.

Advantages

- Eliminates steady-state error.

- Provides a balance between responsiveness and stability.

Disadvantages

- Tuning can be more complex than P or I controllers.

- May lead to slower response compared to a P controller alone.

Click Here to Join the Over 5500 Students Taking our Highly Rated Courses in Manufacturing, Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

5. Proportional-Derivative (PD) Controller

Description

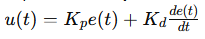

A PD controller combines proportional and derivative actions to provide both quick response and improved stability. The control law is:

When to Use

- Systems that require quick response and improved damping.

- Processes with rapid changes or oscillations.

Advantages

- Improves stability and reduces overshoot.

- Provides quick response.

Disadvantages

- Does not eliminate steady-state error.

- Sensitive to noise.

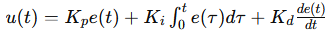

6. Proportional-Integral-Derivative (PID) Controller

Description

A PID controller combines all three actions: proportional, integral, and derivative. The control law is:

When to Use

- Complex systems with significant dynamic changes.

- Processes that require precise control and minimal steady-state error.

Advantages

- Eliminates steady-state error.

- Improves stability and response time.

- Versatile and widely applicable.

Disadvantages

- Tuning can be complex and time-consuming.

- Sensitive to noise in the derivative term.

Click Here to Join the Over 5500 Students Taking our Highly Rated Courses in Manufacturing, Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

7. Adaptive Controllers

Description: Adaptive controllers modify their parameters automatically in real-time to adapt to changing process conditions.

Working Principle:

- Continuously adjusts the controller parameters based on feedback from the process.

- Uses algorithms to identify changes in the process and adapt the control strategy accordingly.

Applications:

- Processes with varying dynamics

- Systems subject to frequent disturbances

- Advanced aerospace applications

Advantages:

- Flexible and can handle process variability

- Reduces the need for manual retuning

Disadvantages:

- More complex and computationally intensive

- Requires sophisticated algorithms and implementation

8. Fuzzy Logic Controllers

Description: Fuzzy logic controllers use fuzzy logic rather than binary logic to handle imprecise or uncertain information.

Working Principle:

- Uses fuzzy sets and rules to map inputs to outputs.

- Mimics human decision-making by handling partial truths.

Applications:

- Non-linear and complex systems

- HVAC systems

- Robotics

Advantages:

- Robust in handling imprecision and uncertainty

- Can be easier to design for complex systems

Disadvantages:

- May require more computational resources

- Designing fuzzy rules and membership functions can be complex

Click Here to Join the Over 5500 Students Taking our Highly Rated Courses in Manufacturing, Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

9. Model Predictive Controllers (MPC)

Description:

Model Predictive Controllers use a model of the process to predict future outputs and optimize control actions.

Working Principle:

- Uses a mathematical model to predict future behavior of the process.

- Solves an optimization problem at each control interval to determine the control action.

Applications:

- Chemical and petrochemical processes

- Multivariable control systems

- Processes with constraints on inputs and outputs

Advantages:

- Handles multivariable systems with constraints

- Can optimize performance over a future time horizon

Disadvantages:

- Computationally intensive

- Requires an accurate process model

10. Neural Network Controllers

Description: Neural Network Controllers use artificial neural networks to learn and adapt to process dynamics.

Working Principle:

- Trained using historical process data.

- Adjusts control actions based on learned patterns and real-time feedback.

Applications:

- Complex non-linear systems

- Systems with unknown dynamics

- Adaptive control in dynamic environments

Advantages:

- Capable of handling non-linear and complex systems

- Can learn and adapt over time

Disadvantages:

- Requires significant training data

- Computationally intensive and complex to design

Click Here to Join the Over 5500 Students Taking our Highly Rated Courses in Manufacturing, Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Conclusion

Selecting the right controller in process engineering is essential for achieving optimal performance and stability. Proportional, Integral, and Derivative controllers provide fundamental control actions that can be combined to suit various process requirements. Advanced control strategies like MPC, adaptive control, fuzzy logic, and neural network control offer enhanced performance for complex and dynamic systems. The choice of controller depends on the specific characteristics of the process, desired control objectives, and practical considerations such as implementation complexity and computational resources.

Some Selected Industry Courses to start today!

1. ISO MANAGEMENT SYSTEMS IMPLEMENTATION & INTERNAL AUDITOR COURSES

- Integrated Management Systems (IMS) Implementation Course

- FSSC 22000 Implementation & Internal Auditor Course

- ISO 22000 Implementation & Internal Auditor Course

- ISO 22000 (HACCP, PRPs, oPRPs and CCPs) for Food Safety

- Certified Internal Auditor (CIA) Training Course

- ISO 9001 (QMS) Implementation & Internal Auditor Course

- ISO 14001 (EMS) Implementation & Internal Auditor Course

- ISO 45001 (OH&SMS) Implementation & Internal Auditor Course

- Food Fraud Mitigation & Defense Certification Course

2. ISO LEAD AUDITOR COURSES

- ISO 50001 Energy Management Systems (EnMS) Lead Auditor Course

- ISO 22000 Food Safety Management Systems (FSMS) Lead Auditor Course

- ISO 14001 Environmental Management Systems (EMS) Lead Auditor Certification Course

- ISO 45001 Occupational Health & Safety Management Systems (OH&MS) Lead Auditor Certification Course

- ISO 9001 Quality Management Systems (QMS) Lead Auditor Course

3. MANUFACTURING, QUALITY, PRODUCT DEVELOPMENT, OPERATIONS & SUPPLY CHAIN MANAGEMENT

- Good Manufacturing Practices (GMP)

- ISO/IEC 17025 – Laboratory Management Systems Certification

- Essentials of Engineering Project Management

- Construction Project Management

- Essentials of Contract Management

- Environmental Impact Assessment (EIA)

- Laboratory Management Systems (LMS) Essentials

- Certified Manager of Quality & Process Excellence

- Essentials of Facility Management

- Agile Project Management

- Engineering Codes, Standards and Specifications

- Industrial Process Safety

- Fundamentals of Risk Management

- Industry 4.0: Digital Transformation in Manufacturing

- Manufacturing Operations Management Certification Course

- Total Quality Management (TQM) Certification Course

- Supply Chain Management (SCM) MasterClass

- Certified Lean Management Professional™ (CLMP™)

- Six Sigma for Business and Manufacturing Process Improvement

- Product Management Certification Course

- Statistical Process Control (SPC) and Data Analysis Course

- Quality Assurance for Business and Operational Excellence

- Lean Six Sigma Yellow Belt Certification Course

- Essentials of Facility Management

- Agile Project Management

- Engineering Codes, Standards and Specifications