Complete Equipment Maintenance Documentation Kit

Ensure your equipment runs at peak performance with the Complete Equipment Maintenance Documentation Kit, a ready-to-download and fully customizable collection of essential maintenance forms, checklists, logs, and SOPs. This kit is designed to support maintenance teams, engineers, and operations managers in achieving effective equipment care, reducing downtime, and staying compliant with Good Manufacturing Practices (GMP), ISO standards, and internal quality protocols. Scroll down for details.....

Learn More

Ensure your equipment runs at peak performance with the Complete Equipment Maintenance Documentation Kit, a ready-to-download and fully customizable collection of essential maintenance forms, checklists, logs, and SOPs. This kit is designed to support maintenance teams, engineers, and operations managers in achieving effective equipment care, reducing downtime, and staying compliant with Good Manufacturing Practices (GMP), ISO standards, and internal quality protocols.

Ideal for manufacturing plants, pharmaceutical production, food and beverage facilities, and other asset-intensive industries, this toolkit equips your organization with a standardized and professional approach to equipment management.

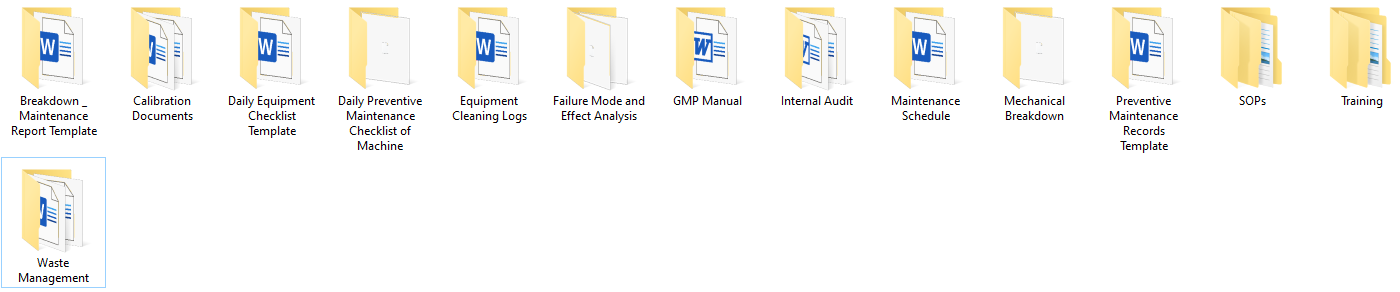

🧰 What’s Included in the Equipment Maintenance Kit?

This powerful toolkit includes 15+ practical, editable templates and documentation tools for every key area of equipment care—breakdown response, preventive maintenance, calibration, cleaning, training, and compliance.

🔧 Core Maintenance Templates

Breakdown Maintenance Report Template

Capture critical details of unplanned equipment failures, root causes, corrective actions, and downtime metrics.Mechanical Breakdown Report

Document mechanical issues systematically, aiding in trend analysis and preventive actions.Preventive Maintenance Records Templates

Schedule, record, and monitor regular maintenance tasks to prevent unexpected failures and prolong asset life.Daily Preventive Maintenance Checklist of Machines

Ensure consistent daily upkeep of key equipment using structured, easy-to-follow checklists.Maintenance Schedule Template

Plan and track periodic maintenance activities across machines, departments, or locations.

📋 Routine Operation & Cleaning Logs

Daily Equipment Checklist Template

Verify operational readiness of equipment daily to catch issues before they escalate.Equipment Cleaning Logs

Maintain hygiene compliance and ensure cleaning tasks are completed, especially in GMP-sensitive environments.

⚙️ Reliability & Failure Analysis

Failure Mode and Effect Analysis (FMEA)

Identify and mitigate risks related to equipment functionality with this structured problem-prevention tool.

🛠 Calibration & Compliance Documentation

Calibration Documents Template

Maintain traceable, audit-ready calibration records for all measurement and inspection devices.Internal Audit Template

Evaluate and improve your maintenance procedures with structured internal audits that track findings and corrective actions.GMP Manual

Align maintenance activities with industry-specific regulatory guidelines to ensure compliance.

📘 Standardization, Training & Waste Control

Standard Operating Procedures (SOPs) – Various Types

A library of editable SOPs to formalize maintenance routines, equipment operation protocols, and safety measures.Training Templates

Track technician training records, equipment-specific certifications, and re-training schedules.Waste Management Templates

Ensure proper disposal and documentation of waste related to maintenance activities, including oil, parts, and hazardous materials.

🧩 Key Features

Fully Editable Formats – Provided in Word, Excel, and/or PDF formats for seamless customization.

Ready to Implement – Save hours of development time with pre-structured, industry-aligned templates.

Compliance Ready – Supports requirements for GMP, ISO 9001, ISO 13485, FDA, and other regulatory frameworks.

Operational Efficiency – Helps reduce breakdowns, improve OEE (Overall Equipment Effectiveness), and extend equipment lifespan.

🎯 Perfect For:

Maintenance Engineers & Technicians

Plant & Facility Managers

Equipment Reliability Teams

Quality Assurance & GMP Compliance Professionals

Manufacturing & Production Teams

Get your operations running smoothly, minimize downtime, and ensure regulatory compliance.

Download the Complete Equipment Maintenance Documentation Kit today and take a proactive step toward asset reliability and maintenance excellence.