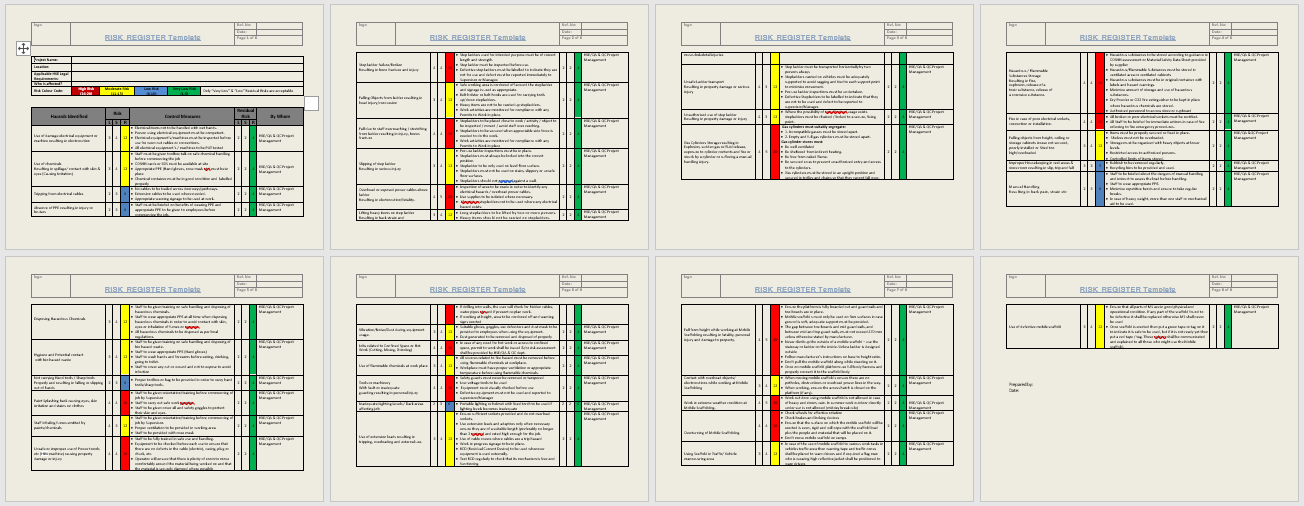

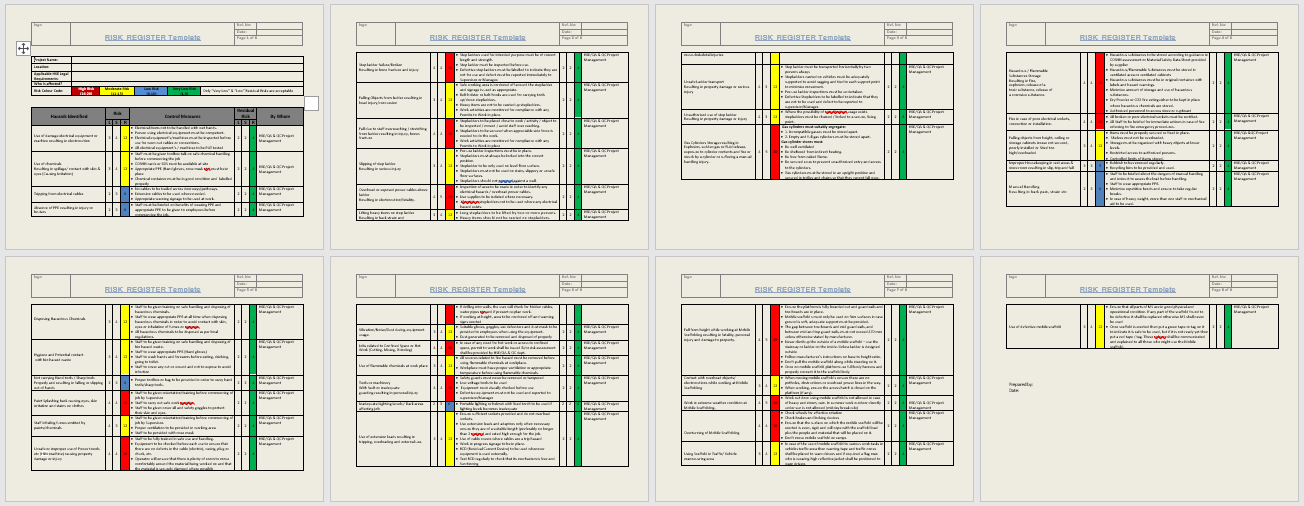

HSE Risk Register Template – FREE Downloadable Document

This FREE HSE (Health, Safety, and Environment) Risk Register is a comprehensive, downloadable template designed to assist safety officers, project managers, and quality assurance teams in identifying, assessing, and mitigating workplace hazards. It is an essential tool for promoting workplace safety and legal compliance, suitable for use across industries including construction, maintenance, manufacturing, and facilities management. Scroll down for details.....

Learn More

This FREE HSE (Health, Safety, and Environment) Risk Register is a comprehensive, downloadable template designed to assist safety officers, project managers, and quality assurance teams in identifying, assessing, and mitigating workplace hazards. It is an essential tool for promoting workplace safety and legal compliance, suitable for use across industries including construction, maintenance, manufacturing, and facilities management.

🗂 Structure & Features

The risk register is thoughtfully structured to document a range of potential hazards, their associated risks, and prescribed control measures. The template follows a standard risk management matrix using the formula:

Risk = Likelihood (L) x Severity (S)

Each risk is assessed twice:

Initial Risk (before control measures)

Residual Risk (after implementing controls)

Color coding helps categorize the risk level:

🔴 High Risk (16–20)

🟠 Moderate Risk (11–15)

🟡 Low Risk (6–10)

🟢 Very Low Risk (1–5) – Only residual risks in this category are acceptable

⚠️ Hazards Identified

The register includes over 35 detailed hazards across various operational scenarios, including but not limited to:

Electrical Safety: Use of damaged electrical equipment, poor socket installations, and overhead power lines.

Chemical Hazards: Spillage, improper storage, and disposal of hazardous substances.

Manual Handling: Lifting heavy items, carrying tools, repetitive motion.

Working at Height: Step ladders, mobile scaffolding risks, fall protection.

PPE Compliance: Injuries due to the absence or misuse of protective equipment.

Confined Space & Hot Work: Risk mitigation through permits and special precautions.

Fire Safety: From flammable substances, poor wiring, and chemical storage.

Noise, Dust, and Vibration: Hazards related to power tool use.

Environmental Conditions: Working during extreme weather conditions.

🛠 Control Measures

Each hazard entry outlines specific, actionable control measures such as:

Conducting toolbox talks and safety inductions

Using appropriate PPE (gloves, goggles, harnesses, etc.)

Regular inspection of equipment and tools

Implementation of signage, cordons, and traffic control

Secure storage practices and permit-to-work systems

👥 Responsibility Assignment

The risk register clearly defines "By Whom" each control measure should be implemented. Typically, responsibilities are designated to:

HSE Department

QA & QC Teams

Project Management

📄 Template Fields Include:

Reference Number

Project Name

Location

Applicable HSE Legal Requirements

Affected Personnel

Risk Levels (Initial and Residual)

Control Measures

Responsible Personnel

✅ Benefits of Using This Register

Enhances regulatory compliance (e.g., COSHH, PPE, working at heights regulations)

Minimizes workplace incidents and injuries

Streamlines hazard reporting and mitigation processes

Encourages a proactive HSE culture

Ready-to-use and fully editable

This ready-to-implement tool is ideal for ensuring that all foreseeable hazards are managed systematically and transparently. Download it now and take the next step toward a safer, compliant, and more efficient workplace.