Lean Six Sigma Kit

Lean Six Sigma is a method that is aimed at systematically removing waste and reducing variation in manufacturing and/or business processes. It combines Lean Enterprise and Six Sigma to eliminate the eight kinds of waste (muda): Defects, Over-Production, Waiting, Non-Utilized Talent, Transportation, Inventory, Motion, and Extra-Processing. Scroll down for more details...

Learn More

Lean Six Sigma is a method that is aimed at systematically removing waste and reducing variation in manufacturing and/or business processes. It combines Lean Enterprise and Six Sigma to eliminate the eight kinds of waste (muda): Defects, Over-Production, Waiting, Non-Utilized Talent, Transportation, Inventory, Motion, and Extra-Processing.

Lean Six Sigma not only reduces process defects and waste, but also provides a framework for overall organizational culture change. By introducing Lean Six Sigma, the mind-set of employees and managers change to one that focuses on growth and continuous improvement through process optimization resulting to increased efficiency and profitability.

This high-quality Lean Six Sigma toolkit will make it easy for you to complete projects in manufacturing and business processes that delivers improvement results.

This toolkit contains customizable templates which are presented in excel spreadsheets, word, and/or PowerPoint formats. They can be edited and customized to suit the required need.

The toolkit contains tools to enhance quality improvement for manufacturing, business and operational processes.

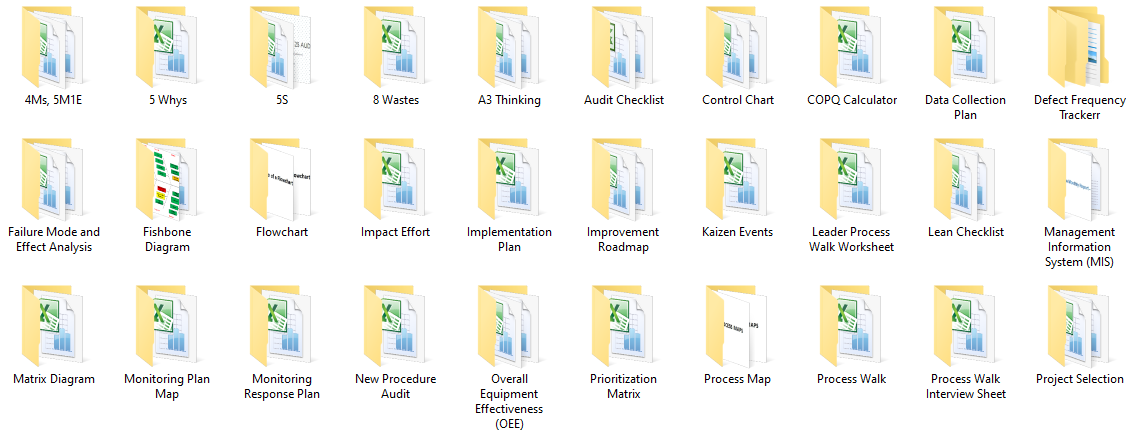

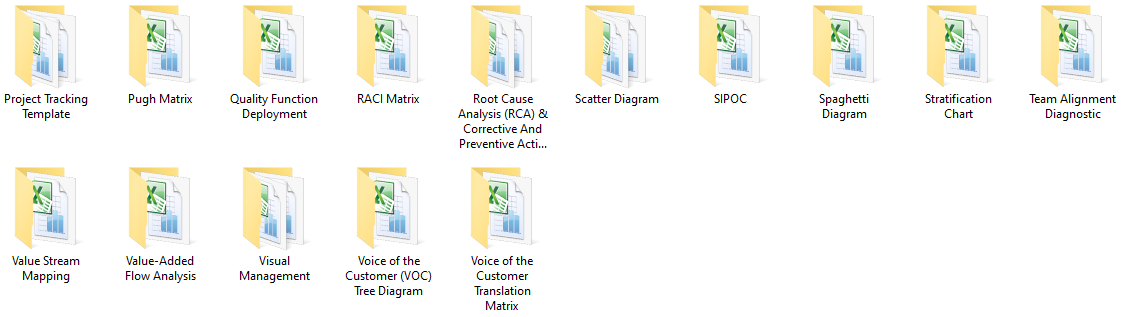

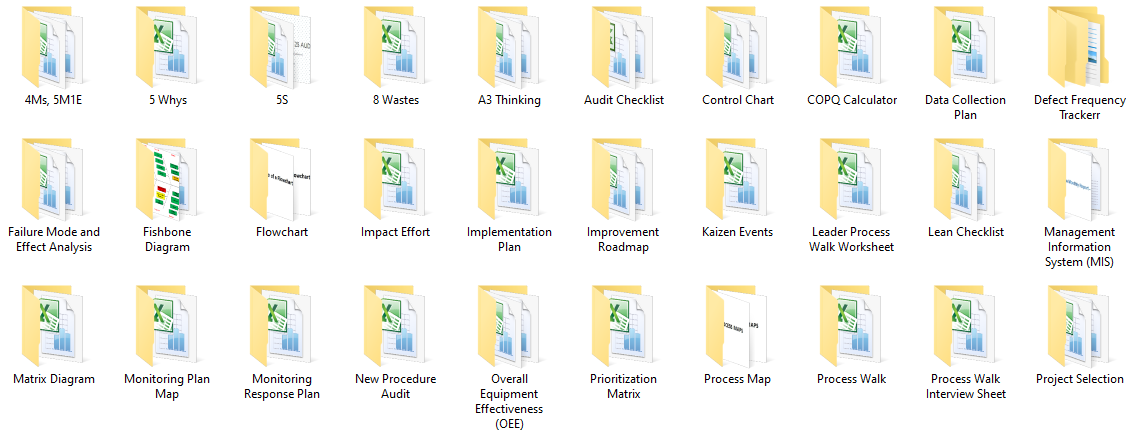

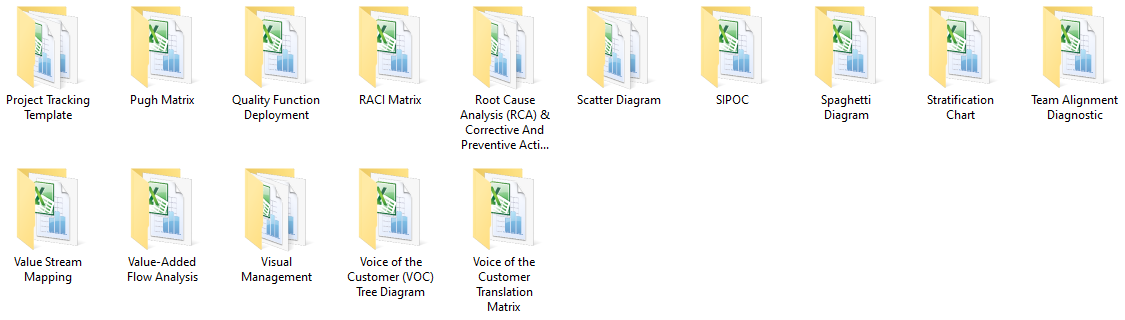

These tools presented in editable formats contains over 100 different templates with examples, ranging from:

- Scatter diagram templates

- Value Stream Mapping

- Overall Equipment Effectiveness (OEE)

- SIPOC Charts

- COPQ Calculator

- Implementation Plan

- Leader Process Walk Worksheet

- Monitoring Plan Map

- Monitoring Response Plan

- New Procedure Audit

- Process Walk Interview Sheet

- RACI Matrix

- Team Alignment Diagnostic

- Value-Added Flow Analysis

- Voice of the Customer (VOC) Tree Diagram

- Voice of the Customer Translation Matrix

- Pareto Charts for Defect Frequency Tracking

- Process Walk

- Flowcharts

- FMEA

- Prioritization Matrix

- 8 Lean Wastes

- Management Information Systems (MIS)

- Kaizen Events

- Stratification Chart

- 5S

- 5 Whys

- Run Chart templates

- Control chart templates

- Stratification chart templates

- Visual management templates

- Pugh Matrix templates

- Quality Function Deployment templates

- Matrix diagram templates

- A3 Analysis templates

- Spaghetti Diagram and many more.