SON Compliance Documentation Toolkit

This comprehensive set of readymade and editable templates is designed to help manufacturers and processors across industries maintain accurate, organized, and compliant records for Production, Quality Control, and Equipment Maintenance, as mandated under the Mandatory Conformity Assessment Programme (MANCAP) and applicable Nigerian Industrial Standards (NIS). Scroll down for details......

Learn More

Ensure your facility is audit-ready with this professionally designed SON Compliance Documentation Toolkit, tailored specifically to meet the inspection and regulatory documentation requirements of the Standards Organisation of Nigeria (SON).

This comprehensive set of readymade and editable templates is designed to help manufacturers and processors across industries maintain accurate, organized, and compliant records for Production, Quality Control, and Equipment Maintenance, as mandated under the Mandatory Conformity Assessment Programme (MANCAP) and applicable Nigerian Industrial Standards (NIS).

Whether you're setting up a new manufacturing facility or streamlining existing operations for audit readiness, these templates will save time, reduce errors, and help demonstrate full compliance during SON inspections.

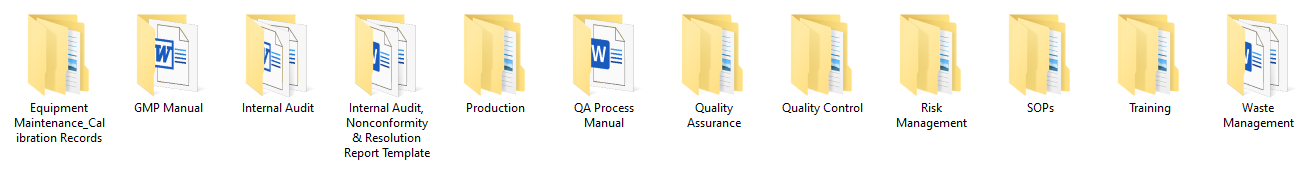

✅ What’s Included in the Toolkit?

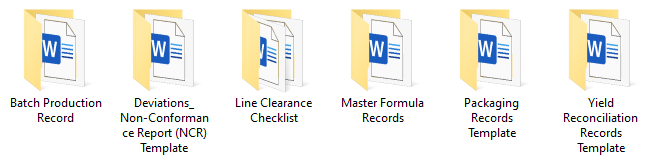

🏭 Production Records Templates

Master Production Formula Sheet

– Document standard quantities, materials, and processing steps.Batch Manufacturing Record (BMR)

– Capture batch-wise details of raw material usage, process parameters, and yields.Line Clearance Checklist

– Pre-batch startup checks to avoid contamination or mislabeling.Production Schedule and Output Log

– Track daily/weekly production targets vs. actuals.Rework/Non-Conformance Report Template

– Document out-of-spec batches and corrective actions.Yield Reconciliation Records Template

Packaging Records Template

Deviations/Non-Conformance Report (NCR) Template

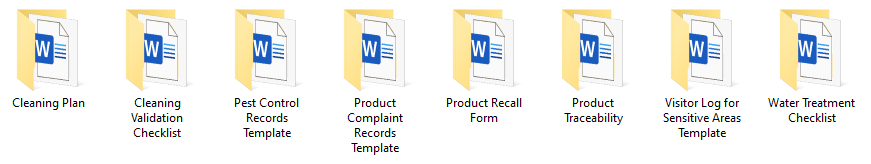

🧪 Quality Control/Quality Assurance (QA/QC) Records Templates

Raw Material Receiving and Inspection Log

– Record supplier information, material status, and inspection results.Certificate of Analysis (CoA) Template

– For raw materials and finished products.In-Process QC Testing Form

– Monitor critical parameters during manufacturing.Finished Product QC Report

– Document lab results, batch approvals, and release authorizations.Customer Complaint Handling Form

– Track complaints, investigations, and resolutions.OOS (Out-of-Specification) Investigation Report

– For thorough documentation of deviations and CAPA.Internal Audit Checklist (ISO 9001/NIS standards-based)

Product Recall Template

Environmental Monitoring Record Templates

Retention Sample Records

Product Traceability Templates

Pest Control Records

Stability Testing Records Template

Product Complaint Records Template

Cleaning Plan & Validation Checklist

Quality/QA Process Manual

Good Manufacturing Practices (GMP) Manual

Internal Audit, Nonconformity & Resolution Report Template

Risk Assessment Checklists & Records Templates

🛠️ Equipment Maintenance & Calibration Templates

Preventive Maintenance Schedule

– Plan and monitor scheduled servicing of machinery and lab equipment.Equipment Maintenance Logbook

– Record all maintenance, repairs, and breakdowns.Equipment Calibration Record Sheet

– Track instrument calibration, frequency, results, and technician sign-offs.Daily Equipment Checklist

– For routine operational checks (e.g., mixers, blenders, compressors, lab devices).Cleaning and Sanitization Log

– Ensure hygiene and operational readiness of equipment.

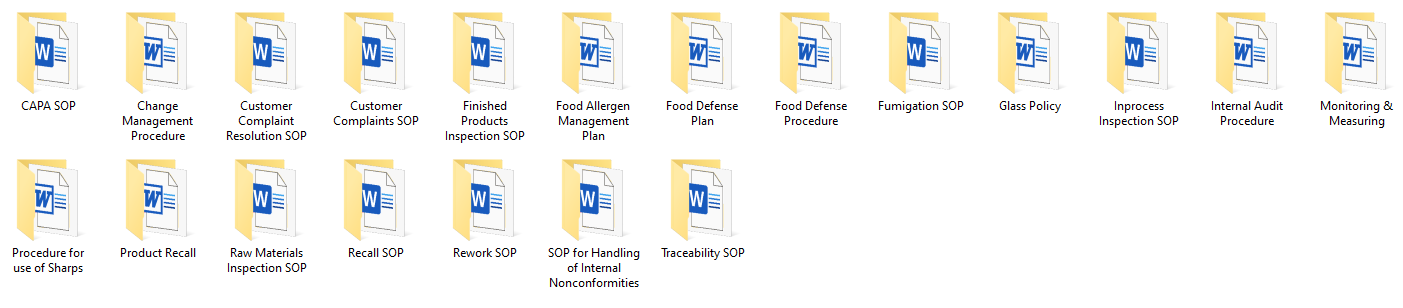

🛠️ Standard Operating Procedures (SOP) Templates

- CAPA SOP

- Change Management Procedure

- Customer Complaint Resolution SOP

- Customer Complaints SOP

- Finished Products Inspection SOP

- Food Allergen Management Plan

- Food Defense Plan

- Food Defense Procedure

- Fumigation SOP

- Inprocess Inspection SOP

- Internal Audit Procedure

- Monitoring & Measuring

- Product Recall

- Rework SOP

- Traceability SOP

- Raw Materials Inspection SOP

- SOP for Handling of Internal Nonconformities

- Glass Policy

- Procedure for use of Sharps

📁 Formats Provided:

Microsoft Word (.docx)

Microsoft Excel (.xlsx)

Printable PDF versions

Easy to customize with your company logo and SOP references

🛡️ Benefits:

Audit-ready documentation for SON inspections

Aligns with NIS, ISO 9001, and GMP documentation expectations

Reduces non-compliance risk and inspection delays

Saves time on document creation and formatting

Ideal for manufacturers, processors, QC/QA teams, and operations managers