रेखा संतुलन - अर्थ, लाभ और तरीके

Line balancing in a layout refers to the arrangement of machine capacity with the aim of securing relatively uniform flow at capacity operation. It is a layout having equal operating times at the successive operations in the complete form of the process.

Line balancing is a useful tool in manufacturing, involving setting a planned rate of production for necessary materials to be fabricated within a particular time frame thus assuring that every line section's production quota can be met within the time frame using the available production capacity. It is an efficient device that is used to develop the throughput of production lines and work cells in the process decreasing manpower requirements and expenses.

Click Here to Join the Over 2000 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2000 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Line balancing is intended to match the production output rate to the production plan enabling on-time delivery, with reduced surplus inventory level. Line balancing is usually practiced to resolve problems occurring in production lines. It is a technique to reduce imbalance between workers and workloads in order to accomplish required run rate (H.Jay and R.Barry, 2006).

An unbalanced production line may lead to poor machinery utilization, a reason for product layout requiring line balancing. A typical example is a production line with work stations A, B and C with each having the capacity to produce 200 items, 100 items, and 50 items per hour respectively.

If each of the machines were to produce only 50 items per hour then each hour the machines at A and B would be idle for 45 and 30 minutes respectively. Such a layout will be unbalanced and the production line needs balancing. Another example is a baking factory with its oven continuously baking loaves at the rate of 800 loaves per hour and the wrapping machine only wrapping 400 loaves per hour. This kind of system is an unbalanced system, thus requiring line balancing.

Click Here to Join the Over 2000 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2000 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Objective of Line Balancing

The following are some of the objectives of Line balancing procedure:

- It assists in managing workloads among operators.

- It is used in recognizing the location of bottleneck.

- It is used in deciding the number of workstations.

- It assists in decreasing production cost.

- It helps in assigning task to each work station in such a way that there is little idle time.

Benefits of Line Balancing

- Helps eliminate bottleneck operations.

- Helps prevent unnecessary duplication of equipment capacity.

- Helps increase production efficiencies and rate.

Click Here to Join the Over 2000 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 2000 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Food Safety, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Methods of Line Balancing

- The first and obvious possibility in the right direction is to increase the output.

- Another possibility is that another product be sent close to the first one so that some idle machines are used jointly.

- The last possibility is to estimate the output of the last work station which can be considered as the minimum output of all the intermediate work stations.

A very important point to note while balancing a machine is that, it is important to see that output of fastest machine be multiple of the output of the remaining other machines.

Click Here to Download Readymade Editable Toolkits & Templates on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HSSE, Project Management etc.

Steps in Line Balancing

There are four steps in solving line balancing described by G. Andrew (2006).

- Draw the Precedence Diagram: Precedence diagram needs to be drawn to demonstrate task relationship between workstations showing the sequence by which tasks are carried out, represented by nodes or graph. The product should not be moved to the next station without completing the previous station.

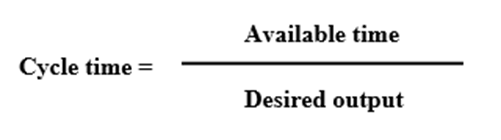

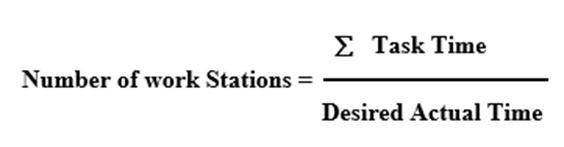

- Determine the Cycle Time: Cycle time is longest time allowed at each station. Cycle time can be gotten by dividing the required units to production time available per day. This is the time expressed in minutes between two simultaneous products coming out of the end of production line. It acts as an indicator to showing how the line is set up to run at that instance, taking into consideration the entire production quantities. Cycle time can be mathematically expressed as follows:

- Assign tasks to the workstation: Distribute tasks to workstation after completing a time cycle in the order of longest task times.

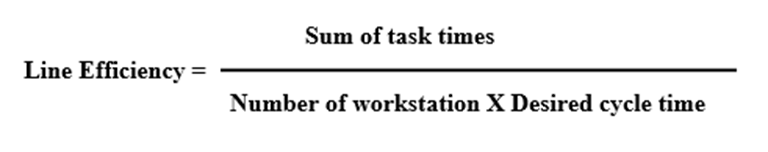

- Calculate the Line Efficiency: Line efficiency is calculated to find effectiveness of the line. The formula is given by:

Click Here to Download Readymade Editable Toolkits & Templates on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, HSSE, Project Management etc.

About the Author

Olanrewaju, Adebayo Bamidele is a Lead Auditor of ISO 9001, FSSC 22000 / ISO 22000, 14001 & 45001 Management Systems, Certified Six Sigma Master Black Belt (CSSMBB), process engineer, and quality management professional with strong working experience and proven skills in manufacturing excellence, ISO management systems implementation, lean / digital manufacturing, and project management.

Adebayo is a Corporate Member of American Institute of Chemical Engineers (AIChE), Associate Member, the Institution of Chemical Engineers (IChemE), Corporate Member, Nigerian Society of Engineers (NSE), Corporate Member, Nigerian Society of Chemical Engineers (NSChE), Associate Member, Nigerian Institute of Management (NIM), and Associate Member, Institute of Strategic Management of Nigeria (ISMN).

He is an author of over 15 books and has published over 45 online courses on various e-learning platforms including Udemy, Alison, Learnformula & Study Plex.

You can reach him, here.