निरंतर सुधार

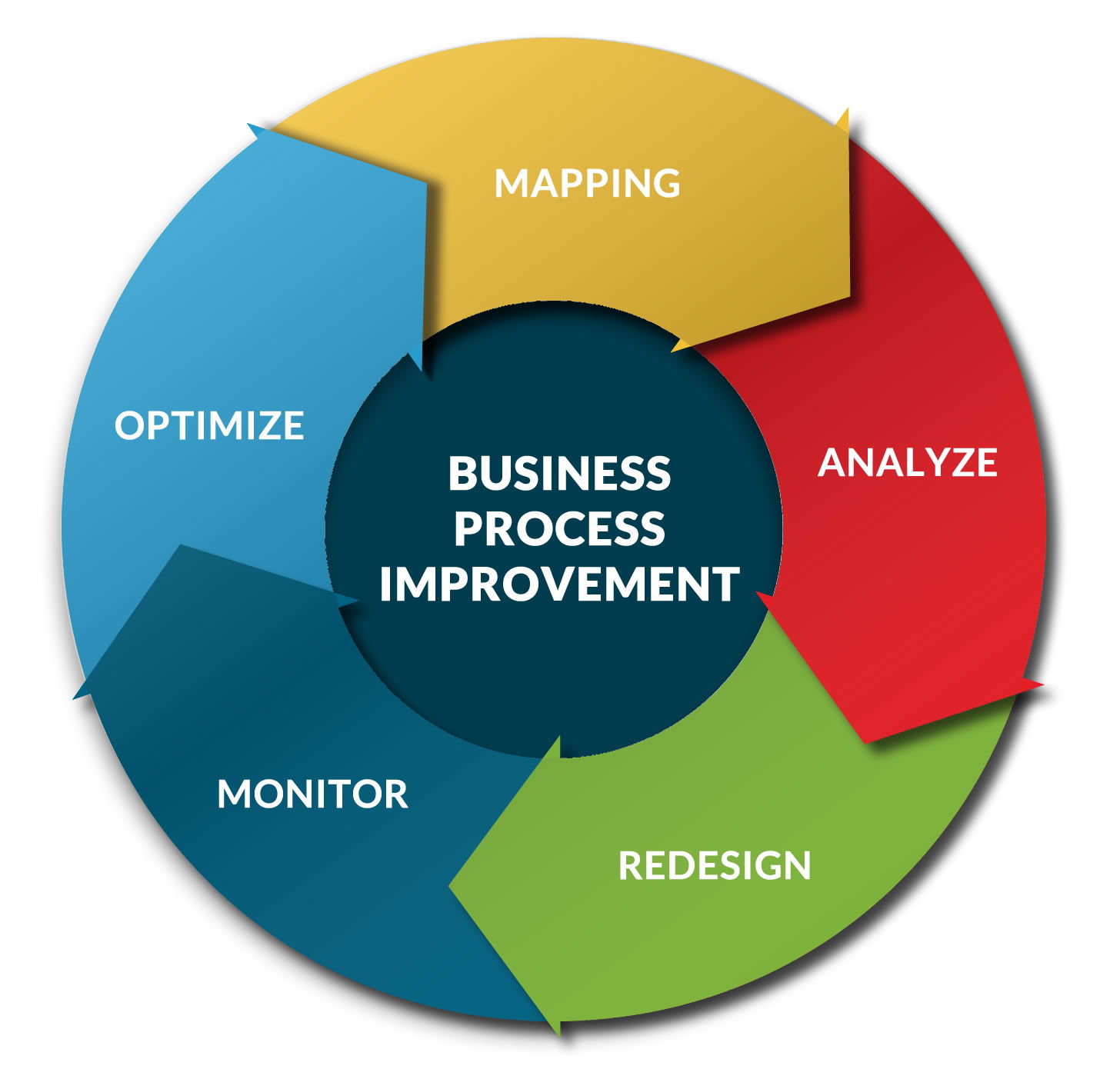

We assist organizations proactively identify, analyze and improve their processes for optimization and to meet acceptable quality standards.

We follow systematic approach which involves some specific methodologies and approaches. These include benchmarking, lean manufacturing, six sigma methodologies etc., each of which focuses on different areas of improvement and uses different methods to achieve the best results. We help spot processes in clients’ organizations that can either be modified or complemented with sub-processes or even eliminated for the ultimate goal of improvement.

Ideal process improvement is an ongoing practice and we encourage our client to always follow up with the analysis of areas of improvement.

The end results of our process improvement activities are measured in the enhancement of product quality, customer satisfaction, customer loyalty, increased productivity, development and improvement of employees’ skills, efficiency and increased profits all of which results in higher and faster return on investment (ROI).

Get a Quote here.