NAFDAC Compliance Documentation Kit

These templates are specifically developed to help manufacturers of regulated products (foods, drugs, cosmetics, medical devices, etc.) maintain structured, complete, and compliant records — a core requirement for factory approval, GMP certification, and post-market surveillance. Scroll down for more details.....

और जाने

Be fully prepared for NAFDAC factory inspections, routine GMP audits, and product registration processes with this all-in-one NAFDAC GMP Compliance Toolkit — a curated set of professionally designed, ready-to-use, and fully editable templates for all critical documentation required by the National Agency for Food and Drug Administration and Control (NAFDAC).

These templates are specifically developed to help manufacturers of regulated products (foods, drugs, cosmetics, medical devices, etc.) maintain structured, complete, and compliant records — a core requirement for factory approval, GMP certification, and post-market surveillance.

Whether you're setting up a new facility or updating your existing documentation, this toolkit will guide you toward seamless compliance with NAFDAC’s expectations under Good Manufacturing Practice (GMP) guidelines.

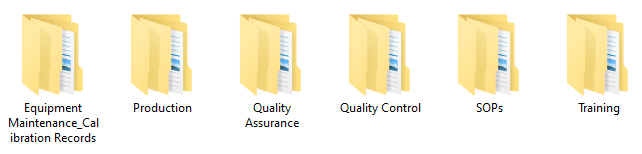

✅ What’s Inside the Toolkit?

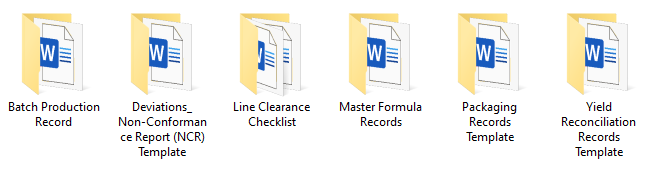

🏭 Production Documentation Templates

Master Production Formula Template

– Document standardized processes, raw materials, quantities, and equipment used.Batch Manufacturing Record (BMR)

– Track each production batch with detailed records of inputs, process steps, and outcomes.Line Clearance Checklist

– Ensure cleanliness and removal of previous materials before new batch production begins.Production Schedule & Output Tracker

– Monitor production planning, actual output, and yield reconciliations.Packaging & Labeling Records Sheet

– Record packaging components, labeling accuracy checks, and batch coding.Yield Reconciliation Records Template

Deviations/Non-Conformance Report (NCR) Template

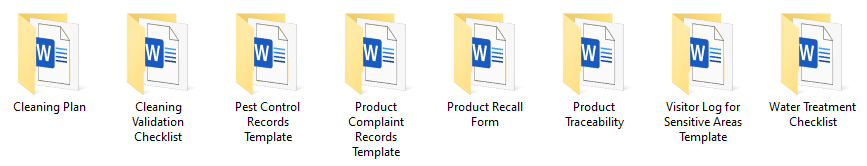

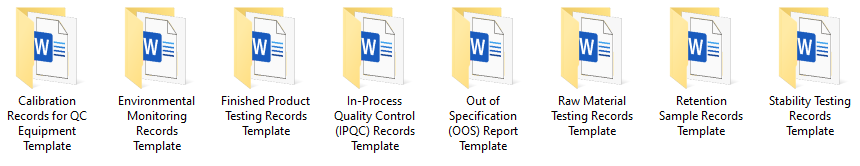

🧪 Quality Assurance/Quality Control (QA/QC) Documentation Templates

Raw Material Receiving and Inspection Log

– Track supplier info, batch numbers, inspection results, and approval status.In-Process Quality Control Checklist

– Monitor quality checkpoints throughout production.Finished Product Testing Report

– Document laboratory analysis, compliance with specifications, and release decisions.Out-of-Specification (OOS) Report Form

– Report and investigate any non-conforming results.Stability Testing Record Template

– Maintain ongoing stability study results to justify shelf life.Retention Sample Logbook

– Record samples stored per batch for post-market evaluation or complaints.Environmental Monitoring Log

– Record microbial load, temperature, humidity, and other critical parameters.

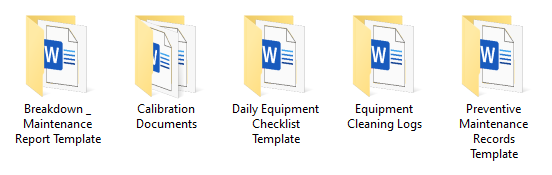

🛠️ Equipment Maintenance & Calibration Templates

Preventive Maintenance Schedule

– Plan and track regular servicing for production and QC equipment.Daily Equipment Checklist

– Conduct routine checks for equipment operability, cleanliness, and safety.Equipment Cleaning & Sanitization Log

– Document cleaning procedures before and after use.Breakdown & Repair Report Template

– Record equipment faults, downtime, and repair details.Equipment Calibration Log

– Track calibration of balances, thermometers, pH meters, and other critical instruments.

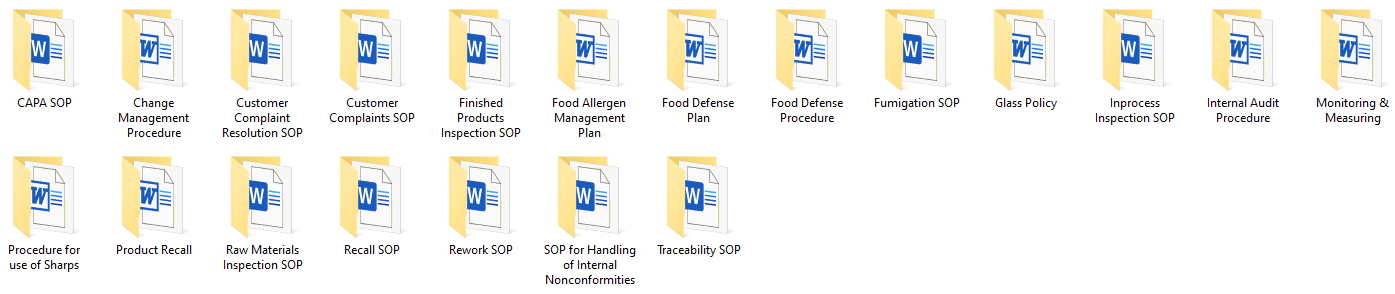

🛠️ Standard Operating Procedures (SOP) Templates

- CAPA SOP

- Change Management Procedure

- Customer Complaint Resolution SOP

- Customer Complaints SOP

- Finished Products Inspection SOP

- Food Allergen Management Plan

- Food Defense Plan

- Food Defense Procedure

- Fumigation SOP

- Inprocess Inspection SOP

- Internal Audit Procedure

- Monitoring & Measuring

- Product Recall

- Rework SOP

- Traceability SOP

- Raw Materials Inspection SOP

- SOP for Handling of Internal Nonconformities

- Glass Policy

- Procedure for use of Sharps

📁 File Formats Provided:

Microsoft Word (.docx)

Microsoft Excel (.xlsx)

Printable PDF versions

Customizable with your company logo and internal SOP references

🎯 Ideal For:

Manufacturers seeking NAFDAC factory approval

Facilities undergoing product registration inspections

Companies implementing or upgrading their GMP systems

Quality Assurance (QA) and Production Managers preparing for audits

🛡️ Key Benefits:

100% aligned with NAFDAC GMP documentation requirements

Ensures inspection and audit readiness

Saves time on document creation

Promotes consistency, traceability, and regulatory compliance

Reduces risk of non-compliance penalties or delays