विनिर्माण प्रक्रियाओं में CTQ (गुणवत्ता के लिए महत्वपूर्ण) मेट्रिक्स के लिए व्यापक गाइड

In manufacturing, achieving consistent product quality is paramount for meeting customer expectations, ensuring compliance with regulatory standards, and maintaining a competitive edge. Critical to Quality (CTQ) metrics are essential components of quality management that help organizations identify, measure, and monitor key attributes that directly impact product quality and customer satisfaction.

This article delves into the concept of CTQ metrics, their importance, how to define them, and how to integrate them into manufacturing processes.

What are CTQ (Critical to Quality) Metrics?

Critical to Quality (CTQ) metrics are the essential attributes or characteristics that significantly impact the quality of a product or service. These metrics are derived from the customer's requirements and are used to translate customer needs into measurable specifications within the manufacturing process. CTQ metrics act as a bridge between customer expectations and operational performance, ensuring that the final product meets or exceeds quality standards.

The Importance of CTQ Metrics in Manufacturing

- Customer Satisfaction: CTQ metrics help manufacturers focus on what truly matters to the customer, ensuring that products meet specific quality standards and expectations.

- Quality Improvement: By identifying and monitoring CTQ metrics, manufacturers can pinpoint areas where quality improvements are needed and implement corrective actions.

- Cost Efficiency: Focusing on CTQ metrics reduces the likelihood of defects and rework, leading to cost savings and more efficient use of resources.

- Compliance and Regulatory Requirements: Many industries have stringent quality standards that must be met. CTQ metrics provide a structured way to ensure compliance with these regulations.

- Competitive Advantage: Consistently delivering high-quality products that meet CTQ metrics can help a company differentiate itself in the market, attracting and retaining customers.

Click Here to Join the Over 6000 Students Taking Highly Rated Courses in Manufacturing, Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

How to Define CTQ Metrics

Defining CTQ metrics involves a systematic approach to identify customer requirements and translating them into measurable process parameters. Here’s a step-by-step process for defining CTQ metrics:

- Identify Customer Needs:

- Conduct Voice of the Customer (VoC) analysis through surveys, interviews, focus groups, or customer feedback.

- Determine what aspects of the product or service are most critical from the customer’s perspective.

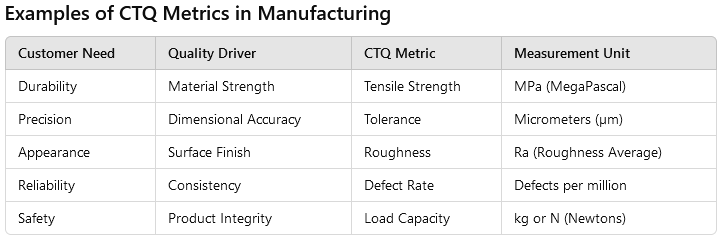

- Develop CTQ Tree:

- Create a CTQ tree to break down broad customer requirements into specific, measurable metrics.

- The CTQ tree typically consists of three levels:

- Customer Need: General statement of what the customer wants.

- Quality Driver: Characteristics that are critical for meeting the customer need.

- CTQ Metric: Quantifiable measurements that ensure the quality driver is met.

- Translate Needs into Measurable Specifications:

- Define how the CTQ metrics will be measured, including acceptable limits, targets, and tolerances.

- Establish clear and precise definitions to avoid ambiguity.

- Prioritize CTQ Metrics:

- Rank CTQ metrics based on their importance to customer satisfaction and their impact on the manufacturing process.

- Focus on high-priority metrics that have the most significant effect on quality.

Click Here to Join the Over 6000 Students Taking Highly Rated Courses in Manufacturing, Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Implementing CTQ Metrics in Manufacturing Processes

Implementing CTQ metrics in manufacturing involves integrating them into quality control, process monitoring, and continuous improvement initiatives. Here's how to do it effectively:

- Incorporate CTQ Metrics into Quality Control:

- Develop quality control plans that incorporate the monitoring of CTQ metrics at various stages of production.

- Use Statistical Process Control (SPC) tools to track CTQ metrics in real time and identify deviations from acceptable limits.

- Use Six Sigma Methodology:

- Six Sigma provides a structured approach to reducing variation in processes, ensuring that CTQ metrics remain within the desired range.

- Utilize tools like DMAIC (Define, Measure, Analyze, Improve, Control) to identify and eliminate root causes of defects that impact CTQ metrics.

- Integrate with Lean Manufacturing:

- Combine CTQ metrics with Lean principles to eliminate waste and improve process efficiency while maintaining quality.

- Use tools like Value Stream Mapping to identify non-value-added activities that affect CTQ metrics.

- Monitor and Analyze Data:

- Collect data on CTQ metrics regularly and analyze trends using control charts, histograms, and Pareto analysis.

- Implement corrective actions when CTQ metrics deviate from established limits.

- Train Employees on CTQ Awareness:

- Ensure that all employees understand the importance of CTQ metrics and their role in achieving quality objectives.

- Provide training on how to measure and monitor CTQ metrics as part of daily operations.

Click Here to Join the Over 6000 Students Taking Highly Rated Courses in Manufacturing, Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Tools for Monitoring CTQ Metrics

- Statistical Process Control (SPC): Utilizes control charts to monitor process variations and ensure CTQ metrics remain within control limits.

- Failure Modes and Effects Analysis (FMEA): Identifies potential failure modes that could impact CTQ metrics and implements preventive measures.

- Root Cause Analysis (RCA): Helps identify and address the underlying causes of deviations in CTQ metrics.

- Process Capability Analysis: Assesses the capability of manufacturing processes to meet CTQ metric specifications.

Challenges in Implementing CTQ Metrics

- Identifying the Right Metrics: Determining which metrics are genuinely critical to quality can be challenging, especially in complex manufacturing environments.

- Data Collection and Analysis: Consistently collecting accurate data and analyzing it can be resource-intensive.

- Change Management: Introducing CTQ metrics may require changes in processes, equipment, or employee behavior, which can encounter resistance.

Click Here to Join the Over 6000 Students Taking Highly Rated Courses in Manufacturing, Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Case Study: CTQ Metrics in Automotive Manufacturing

An automotive parts manufacturer wanted to improve the quality of brake pads produced. The company identified customer needs, such as safety, durability, and performance, and defined CTQ metrics accordingly:

- CTQ Metric 1: Friction Coefficient – Ensuring consistent braking performance

- CTQ Metric 2: Wear Rate – Ensuring durability over the product's lifespan

- CTQ Metric 3: Thickness Variation – Maintaining uniform brake pad thickness for safety

By implementing SPC and Six Sigma techniques, the manufacturer achieved a 30% reduction in defects, resulting in improved product reliability, reduced warranty claims, and increased customer satisfaction.

Conclusion

CTQ (Critical to Quality) metrics are powerful tools for ensuring that manufacturing processes deliver products that meet customer expectations and quality standards. By identifying, measuring, and monitoring CTQ metrics, manufacturers can drive continuous improvement, enhance customer satisfaction, and maintain a competitive edge in the market. Integrating CTQ metrics with quality management frameworks like Lean Six Sigma can further optimize processes and ensure that quality remains a core focus in manufacturing operations.

By effectively implementing CTQ metrics, organizations can not only reduce defects and improve efficiency but also build a reputation for quality that drives long-term success in the manufacturing industry.

Top 50 Courses to Enhance your Skills Today!

1. ISO MANAGEMENT SYSTEMS IMPLEMENTATION & INTERNAL AUDITOR COURSES

- Integrated Management Systems (IMS) Implementation Course

- FSSC 22000 Implementation & Internal Auditor Course

- ISO 22000 Implementation & Internal Auditor Course

- ISO 22000 (HACCP, PRPs, oPRPs and CCPs) for Food Safety

- Certified Internal Auditor (CIA) Training Course

- ISO 9001 (QMS) Implementation & Internal Auditor Course

- ISO 14001 (EMS) Implementation & Internal Auditor Course

- ISO 45001 (OH&SMS) Implementation & Internal Auditor Course

- Food Fraud Mitigation & Defense Certification Course

2. ISO LEAD AUDITOR COURSES

- ISO 50001 Energy Management Systems (EnMS) Lead Auditor Course

- ISO 22000 Food Safety Management Systems (FSMS) Lead Auditor Course

- ISO 14001 Environmental Management Systems (EMS) Lead Auditor Certification Course

- ISO 45001 Occupational Health & Safety Management Systems (OH&MS) Lead Auditor Certification Course

- ISO 9001 Quality Management Systems (QMS) Lead Auditor Course

3. MANUFACTURING, QUALITY, PRODUCT DEVELOPMENT, OPERATIONS & SUPPLY CHAIN MANAGEMENT

- Good Manufacturing Practices (GMP)

- ISO/IEC 17025 – Laboratory Management Systems Certification

- Essentials of Engineering Project Management

- Construction Project Management

- Essentials of Contract Management

- Environmental Impact Assessment (EIA)

- Laboratory Management Systems (LMS) Essentials

- Certified Manager of Quality & Process Excellence

- Essentials of Facility Management

- Agile Project Management

- Engineering Codes, Standards and Specifications

- Industrial Process Safety

- Fundamentals of Risk Management

- Industry 4.0: Digital Transformation in Manufacturing

- Manufacturing Operations Management Certification Course

- Total Quality Management (TQM) Certification Course

- Supply Chain Management (SCM) MasterClass

- Certified Lean Management Professional™ (CLMP™)

- Six Sigma for Business and Manufacturing Process Improvement

- Product Management Certification Course

- Statistical Process Control (SPC) and Data Analysis Course

- Quality Assurance for Business and Operational Excellence

- Lean Six Sigma Yellow Belt Certification Course

- Essentials of Facility Management

- Agile Project Management

- Engineering Codes, Standards and Specifications