कानो मॉडल विश्लेषण: यह कैसे काम करता है और उत्पाद योजना के लिए इसका उपयोग कैसे करें

It may not be enough for a product to just be able to perform the function it is designed for or fulfil the basic need it is built for. This is because a product that works and fulfils its purpose can eventually become boring in the long run and may result to little or no return to the manufacturer with time especially as more and more of such kind of products start to appear in the market. For example, a car that has self-driving functionality is more impressive, goes beyond the basic needs, and makes a customer think ‘wow’ than the conventional ones.

Kano analysis approach can help to quickly increase the customers’ satisfaction level by launching a few great, new features, rather than lots of basic ones ‘as in’ as it were, other similar products. The model helps to prioritize which of the ideas or features are most valuable, so as to be able to make effective business decisions to maintain a competitive advantage in the market.

Click Here to Join the Over 950 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 950 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

The Kano Model is an approach used in prioritizing features on a product roadmap with respect to the degree with which they are likely to satisfy customers. It’s a system that helps manufacturers to prioritize initiatives such as determining which features will satisfy or even delight customers. The model helps to prioritize new features of product or services by grouping them into categories ranging from those that could disappoint a customer to those that are likely to satisfy or even delight customers. The primary consideration for any new feature in Kano model is how much the new feature or product will satisfy the intending customers. The goal is maximizing profits by making the customers happy through additional efforts.

Kano model was created by Dr. Noriaki Kano, a professor of quality management at the Tokyo University of Science in 1984 while researching the factors that contributed to customer satisfaction and loyalty.

Click Here to Join the Over 950 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 950 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Categories of Features of Kano Model

Indifferent features

These are features in a product which customers won’t care about.

Dissatisfaction features

These features serve to upset customers.

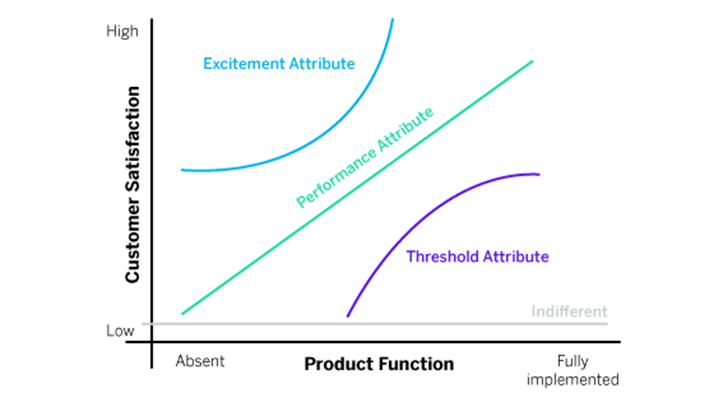

Threshold features

These features are required for a product to be competitive. These features are expected by the customers and are often taken for granted by them. What this means is that they must be included, without which may lead to dissatisfaction.

Excitement features

These features yield a disproportionate increase in customer delight as more investment is made on them. These features are the unique innovations included in the product. If they are not present, customers might not miss them and, if they are included and you continue to invest in them, a very high customer delight is created. Dr. Noriaki called them “the delighters” because of their delightful effect on users, with a resulting positive response to the product.

Performance features

The performance features gives a proportionate increase in customer satisfaction as you invest in them. One example would be increasing file storage capacity in an online app. Dr. Noriaki described it as “one-dimensional” due to the linear relationship between how much investment can be made in it and the resulting amount of customer satisfaction.

Click Here to Join the Over 950 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 950 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

When to Use Kano Analysis

Use Kano Analysis when:

There is a limited time

The Kano model proves to be a great tool to speed up decision-making when there is need to meet up with a tight deadline.

There are limited resources

Kano analysis requires very minimal resources. All that may be required for carrying out Kano analysis may be a simple email questionnaire. This means that you don’t need expert resources to do the research involving Kano model.

You want to see what makes your customers happy

When you’re looking to ‘think outside of the box or ‘think big, you can use Kano analysis to see what features customers would find really impressive and makes them happy for value added.

You want to improve a current product or service

Kano analysis will assess all feature options and give clear choices when trying to update your product offering to maintain a competitive advantage against market competition.

Click Here to Join the Over 950 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 950 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Lean Six Sigma, Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

How to Use the Kano Model

Customer satisfaction is the heart Kano Model Analysis. This means that before adopting the model you need to be sure to find out what the customers really value, their likes, what they love, and what they dislike. After this, you can now follow the steps as outlined below:

Feature Research

This first step involves researching and brainstorming all of the possible features and attributes of the product or service, and all that can be done to ensure that the customers are fully satisfied.

Feature Classification

The next stage is to categorize the features as Not Relevant, Threshold, Performance or Excitement Attributes. The ‘Not Relevant’ are features in the product or services that do not add value to customers, hence they don’t care about them.

Threshold Alignment

This entails making sure that the product or service contains all of the essential basic features. If necessary, some Performance features may be eliminated so they can be included as among the basic or threshold features.

Assess the Excitement Attributes

This step involves evaluating the Excitement features, and finding out about how some of them can be incorporated into the product or service. Again, if necessary, some Performance attributes can be shifted to the excitement attribute so more investment you can be made in the Excitement feature.

Selecting the Performance Attribute

This entails choosing the Performance Attributes in such a way as to still be able to deliver at a competitive price, while still maintaining an acceptable profit margin.

About the Author

Adebayo is a thought leader in continuous process improvement and manufacturing excellence. He is a Certified Six Sigma Master Black Belt (CSSMBB), Digital Manufacturing Professional and ISO Management Systems Lead Auditor (ISO 9001, 45001 & ISO 22000) with strong experience leading various continuous improvement initiative in top manufacturing organizations.

You can reach him here.