केन्द्रापसारक कंप्रेसर वृद्धि और नियंत्रण को समझना

Ask a chemical or mechanical engineer, what does a compressor surge do, and he would shudder merely thinking of the consequences. The centrifugal compressor is the heart of any oil & gas facility and since the last 100 years has been subjected to scrutiny as to what is the perfect control mechanism.

Surge in a centrifugal compressor can be simply defined as a situation where a flow reversal from the discharge side back into the compressor casing occurs causing mechanical damage

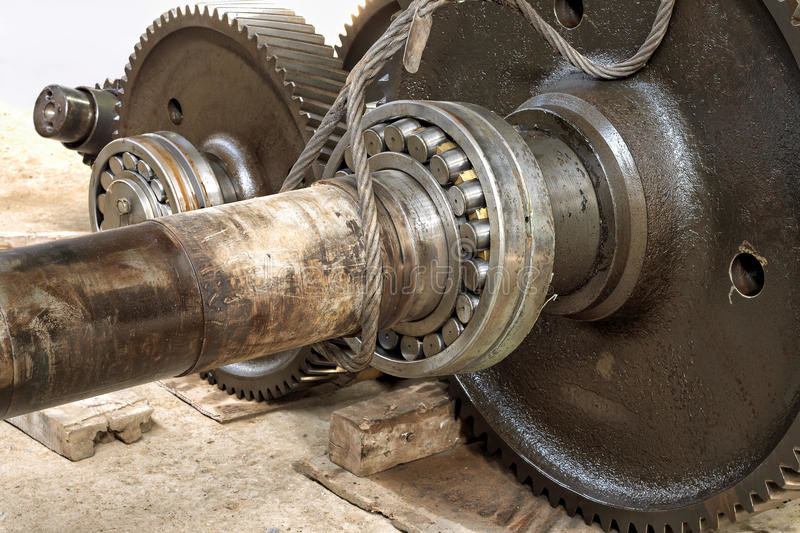

The reasons are multitude ranging from driver failure, power failure, upset process conditions, startup, shutdown, failure of anti-surge mechanisms, check valve failure, operator error, etc. The consequences of a surge are more mechanical in nature whereby ball bearings, seals, thrust bearing, collar shafts, impellers, etc wear out and sometimes depending on the how powerful are the surge forces, cause fractures to the machinery parts due to excessive vibrations.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Here is an image, that shows the bearings being dislodged from its containment. The effects of surge is also contagious and due to excessive shaft vibrations, the gearbox connected between the compressor and the driver are also not spared at the bearings and gear teeth.

The power of a surge is also proportional to the capacities (flow, power, pressure ratio) and even in the case of small turbo compressors, the gear teeth wear out when the impeller rotates in the opposite direction during a surge. The bottom line is - Always avoid a surge in rotating equipment.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Protecting a Centrifugal Compressor from Surge

Anti-surge Valve (ASV) (a.k.a) Cold Gas Recycle

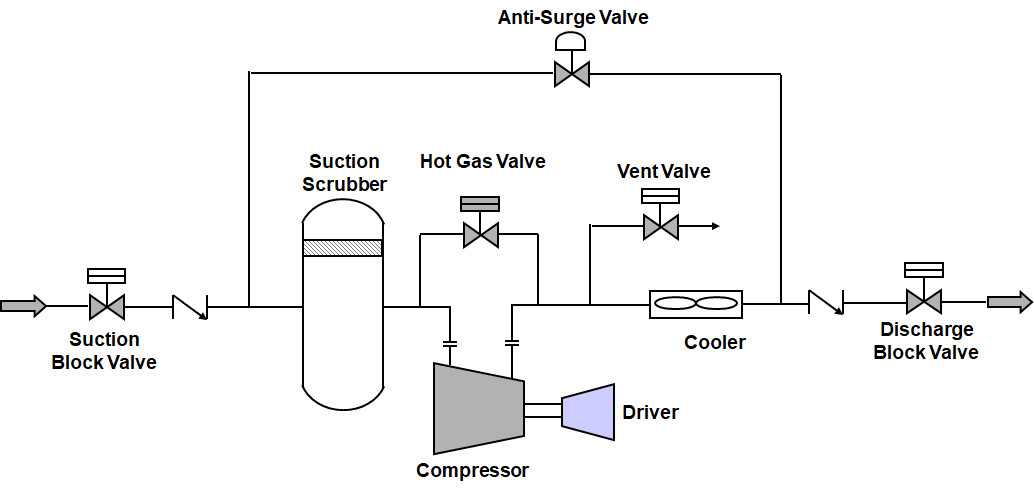

The chief protecting agent of a centrifugal compressor is the anti-surge line/valve that recycles cold gas from the discharge side cooler back to the suction scrubber to keep the operating point away from the surge line.

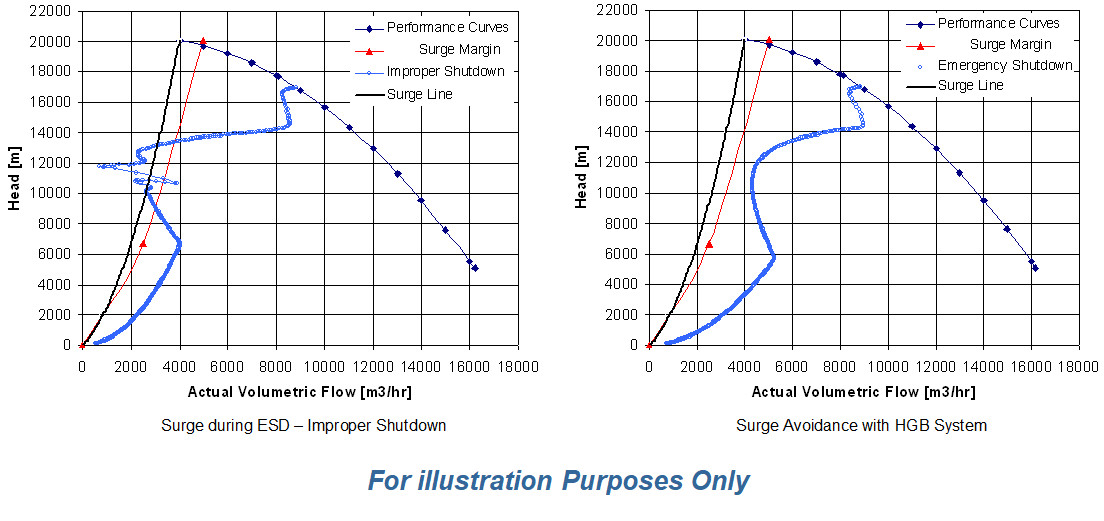

Hot Gas Recycle

Although the anti-surge valve (ASV) is the chief protector, in brownfield projects, often the ASV becomes inadequate to deal with a compressor surge due to addition of new compressors in parallel or series (e.g., booster compressors), change of plant piping or change of vapour composition. In these situations, a necessity arises to recycle more flow for which an additional ASV with quick opening characteristics is installed in parallel to the first ASV. When such solutions still fail to stop a surge event from occurring, a hot gas recycle (a.k.a HGV) is used as a last resort. The second image below shows a gas compressor with a hot gas recycle and whose operating point moved away from the surge line during an emergency shutdown.

In recent decades, with tools such as dynamic simulation, the quantity of hot gas to be recycled can be determined without recycling immoderate amounts of hot gas that can overheat the gas compressor with bearings and seals failing. Excessive hot gas recycle also shortens the efficacy of the lube oil that is used for lubrication purposes.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

The Hot gas recycle valve is always to be used in tandem with the ASV and only during an emergency shutdown (ESD). A hot gas recycle/bypass system consists of piping with an On-Off Valve that is motor operated and can have a full opening time of < 1 sec (for valves between 4” to 16”). For larger On-Off Valves (above 16”), the time is taken to be < 2 sec. In the case of an electric motor driven compressor, the power source for the motor operated HGV must be independent lest during a power failure the motor operated HGV becomes futile.

The hot gas piping should also be laid as short as possible between the discharge line and suction line to have a fast response. During an ESD scenario (e.g., power loss), taking a conservative approach for design purposes, the control output signal from the compressor driver after a trip, takes ~300 milliseconds to reach the Distributed Control System (DCS) and another ~300 milliseconds from the DCS to reach the HGV to open. However with advances in technology, these timings can be considered at ~100 milliseconds.

In simple terms, a lower response time increases the chances of responding faster to a compressor surge.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Deviations from Design Criteria

As a thumb rule, the hot gas system is sized for 50% (max) during FEED stage. However this needs to be checked with a dynamic simulation study since over-sizing the Hot gas system can cause the compressor to overheat the bearings and seals. As per API 617 (7th Edition, 2002), Clause 2.7.1.3, it states,

As a design criteria, bearing metal temperatures shall not exceed 100°C (212°F) at specified operating conditions with a maximum inlet oil temperature of 50°C (120°F). Vendors shall provide bearing temperature alarm and shutdown limits on the datasheets.

However clause No. 2.7.1.3.1 of the said document also says,

In the event that the above design criteria cannot be met, purchaser and vendor shall mutually agree on acceptable bearing metal temperatures.

In reality, the Author has seen cases, where this deviation was taken up to ~135 deg.C depending on the manufacturer and believes that this is due to a variation of operating conditions between string test conditions and actual conditions.

Nevertheless, compressor operating temperatures must never exceed the stipulated or mutually agreed values in order to protect the compressor's internals.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Compressor Control Systems

In today's world no piece of machinery can be said to be protected by modern methods without implementing a control system. A surge can occur in a matter of seconds or sometimes even milliseconds giving almost no time for operators to intervene. Hence a control system becomes a part and parcel of the compressor package.

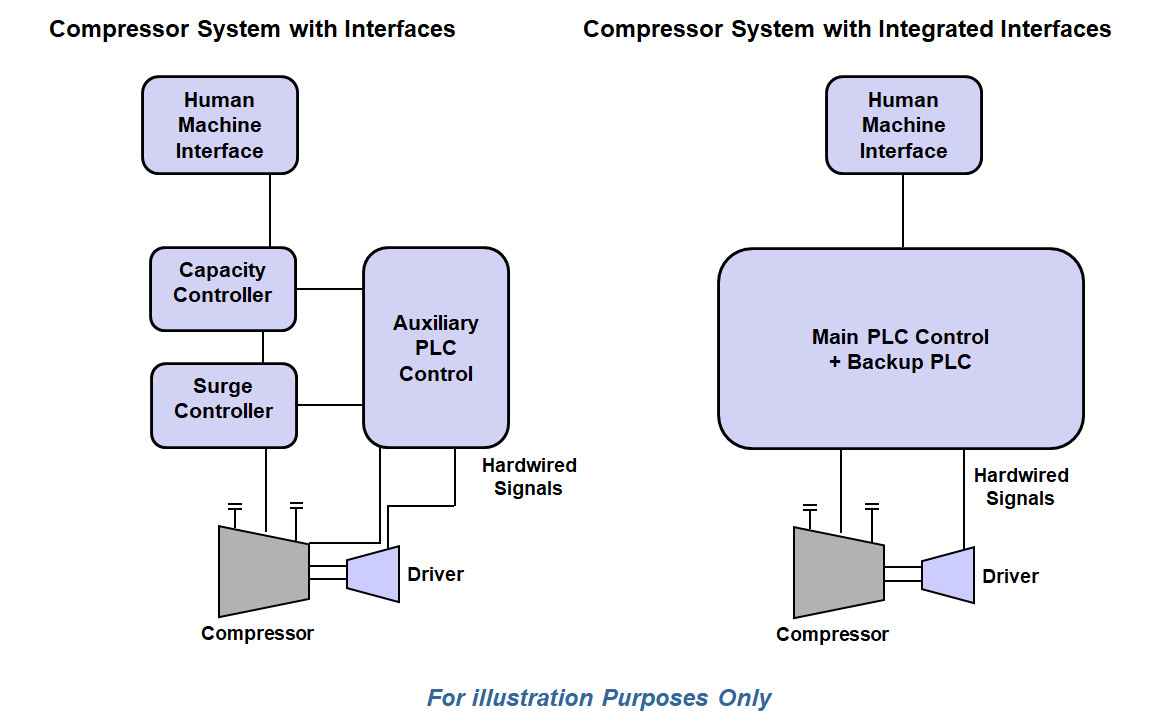

Although the good old Proportional-Integral-Derivative (PID) control was enough to avoid a surge by minimizing the compressor recycle flow, it did not aid much in reducing / optimizing the power requirements. With a steady rise in the oil consumption since the 1970s, the necessity of energy efficiency, safety and environmental friendliness became a priority and demanded better control systems. To respond quickly to any process upsets, high computational speeds in controllers also became a necessity. This led to the rise of specialized control equipment known as 'Black Boxes' that was the alternate to panel mounted instruments. Black boxes though addressed response times, suffered from frequent hardware and software revisions. Black box technology was proprietary with their own coding languages and often experienced compatibility issues when interfacing between different manufacturer's/models. This also meant having to sometimes shutdown the machinery causing monetary implications and increased downtime if not made part of plant maintenance.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

The Advent of Programmable Logic Controller (PLC)

With the limitations of using black box technology being recognized, industry honchos realized the necessity of standardizing and generalizing control systems and their respective programming languages. These standardization efforts led to documenting the IEC 61131 (International Electrotechnical Commission Standard for Programmable Controllers) in 1993 and subsequently revised in 2003.

Programmable Logic Controllers (PLCs) provided not only the computational power but also were easily integrate-able to the compressor controls. PLC's offered the advantage of scalability where new I/O could be added during any form of plant modification / expansion depending on the type of PLC used (e.g., modular or stacked). PLCs also offer Diagnostics capabilities, for example, to trace through the logs of controller output/data during a fault analysis.

In earlier systems that depended on the black box principle, a primary PLC is supplemented with an auxiliary PLC that controlled systems like lube oil, seal oil / dry gas seals, startup sequencing, interlocks, etc. This also required interfacing them properly to allow operators to diagnose and do a root cause analysis in the event of, for example, a compressor trip. However with integrated systems, that used a dedicated control PLC with a backup PLC and the necessary hard wiring, the cost of implementation also comes down while offering better efficiency, diagnostics, generic parts and scalability.

Ref: [1], [2], [3], [4], [5], [6]

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

Click Here to Join the Over 3200 Students Taking our Highly Rated Courses on Quality Assurance/Quality Control, Project Management, Engineering, Food Safety, Lean Six Sigma, Industrial Safety (HSE), Lean Manufacturing, Six Sigma, ISO 9001, ISO 14001, ISO 22000, ISO 45001, FSSC 22000, Product Development etc. on UDEMY.

About the Author

Vijay Sarathy holds a Master’s Degree in Chemical Engineering from Birla Institute of Technology & Science (BITS), Pilani, India and is a Chartered Engineer from the Institution of Chemical Engineers, UK. His expertise over 16 years of professional experience covers Front End Engineering, Process Dynamic Simulation and Subsea/Onshore pipeline flow assurance in the Oil and Gas industry. Vijay has worked as an Upstream Process Engineer with major conglomerates of General Electric, ENI Saipem and Shell.